Gaseous Fire Extinguishing Systems

Critical Volumes Fastest Extinguishing Discipline

Environmentalist

Does not trigger global warming

Quick

Provides early detection and intervention

Effective

Extinguish fire directly

Has a Wide Usage Area

gas fire extinguishing

System Types

By providing three-dimensional protection against fire, it reduces the temperature in the environment, cools the fuel, and disconnects it from oxygen.

Wide Range of Use

Application Areas of Gas Extinguishing Systems

Solid (A), Fuel It minimizes damage in the fight against (B) and C (Electrical) class fires.

CO2 Systems

These systems are generally preferred to ensure the safety of transformers with openings that cannot be closed and devices in an open environment (turbine, generator, etc.). Sıvı yangınlarında lokal uygulama ile doğrudan yakıtın soğutulmasında oldukçaaIt is very successful in directly cooling the fuel with local application in liquid fires. başarılıdır.

Choosing the Right System

Comparison of Gas Extinguishing Systems

Compact – Fast – Low Cost

Systems that end the fire incident in less than 2 minutes.

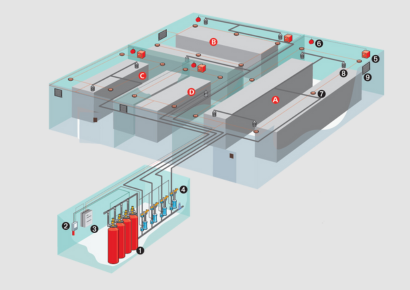

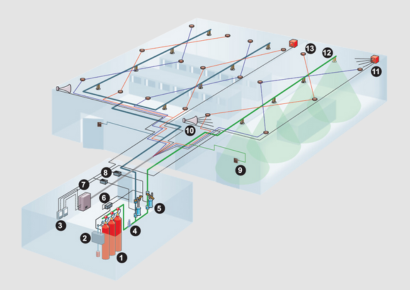

Triggering Gas Extinguishing Systems

Fire Detection System

Fire Detection Panel

Triggering of gas extinguishing systems occurs via a conventional panel.

Detectors

Two different independent detection lines are used using smoke, heat, or flame detectors.

Warning and Alarm Devices

Sirens and flashers are used inside and outside to evacuate the volume before extinguishing.

Supervisory Connections

The central detection system remotely monitors error and alarm information on the extinguishing panel.

Although gas extinguishing systems do not have direct negative effects on human health, exposure to large volumes of these gases (except CO2) for a long time can cause health problems. Each individual’s health condition is different. For this reason, even if the systems are designed within safe ranges, even systems that do not exceed the NOAEL and LOAEL limit values may pose a health hazard.

In cases where the wrong detector is selected and the environmental conditions are not analyzed correctly, the systems may be activated even in situations where there is no fire. This situation may disrupt the processes in the business and cause financial losses due to refilling and commissioning of the systems.

For this reason, when choosing the right gas extinguishing system, the fire detection system should also be made by experts in this field. When the installation work of the systems is completed, before commissioning these systems in a fully automatic mode, possible errors and false alarms should be monitored and equipment changes should be made if necessary.

NOAEL – The highest dose at which no toxic or adverse effects were observed.

LOAEL – The lowest dose at which any toxic or adverse effects were observed.

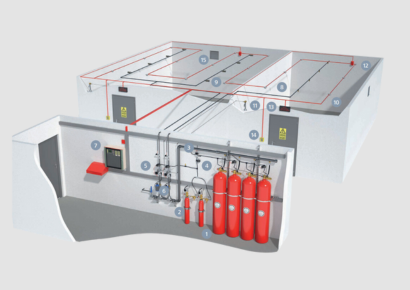

Integrity Test

Doorfan Room

Leak Test

When the gas extinguishing system is used with the total volume protection approach, the sealing of the protected volume is of great importance. The gas released into the room must remain in volume for a certain period of time (depending on the room volume) according to the requirements in the regulation. Thus, the risk of re-flare is eliminated.

Room tightness testing is carried out with the following steps:

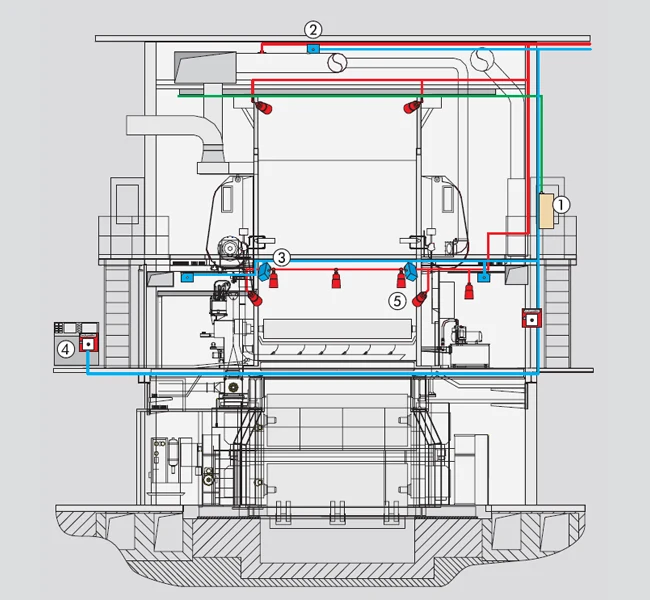

Local CO2 Application Areas

Printing Industry

Fire Protection

Printing machines process highly hazardous and flammable materials due to the risk of fire. When factors such as friction and overheating are included in the equation, flammable materials such as paper, solvents and other chemicals can easily ignite and cause rapidly spreading fires. To eliminate this risk, local surface and area applications of carbon dioxide are used. CO2, an effective refrigerant and suffocating gas, has the ability to quickly extinguish fires.

Room tightness testing is carried out with the following steps:

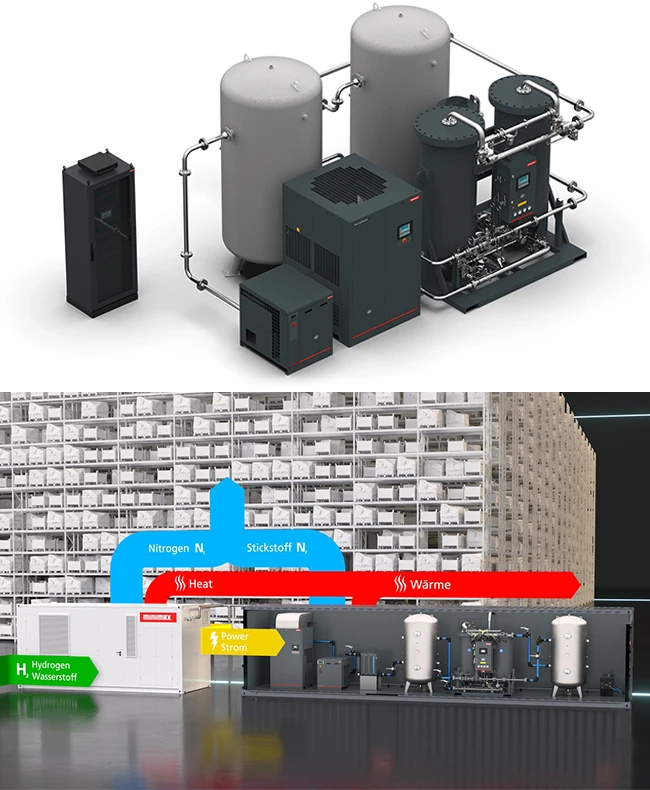

Fire Prevention Technology

Oxygen Reduction Systems

While other gas extinguishing systems stop the fire triangle by changing the concentration of oxygen in the environment in case of fire, oxygen reduction systems have a constantly active cycle. The air we normally breathe contains 21% oxygen. This value is above the 16% value required for the fire reaction to start. These systems, which are used to keep the rate of oxygen in the air below 16%, constantly send nitrogen to the environment. As oxygen is removed from the environment, an unfavorable environment is provided for fire to occur in the protected volume. This required nitrogen is supplied from the outside air via a generator.

Oxygen Reduction System Types:

Fire Safety & Building Technologies

For detailed information

Contact us

Sistem tasarımı, ürün sertifikaları, yatırım maliyeti, uygulama ve montaj sonrası işletme prosedürleri gibi merak ettiğiniz tüm soruları yanıtlamak için buradayız.

Our Phone Numbers:

+90 232 111 22 33 (TR)

+99 897 036 15 84 (EN)